Sheet Metal Bending: what you need to know

How to choose the best bending? How is springback calculated?

The best technologies for sheet metal work

The entire production process is characterized by the use of advanced operating machines and machine tools.

Materials for the bent sheet metal:

The technology used for cutting and bending the sheets allows the use of different types of metal materials, also those with high chemical resistance properties such as AISI 316 and 304 stainless steel, used for mechanical processing in many sectors.

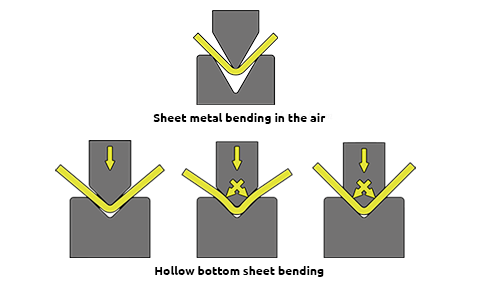

3 types of sheet metal bending

There are three main sheet metal bending techniques which vary according to the field of application and the material chosen.

- The most frequently used mode is definitely the air bending. It uses a punch that presses the metal piece into a V-shaped die below. The bend angle will be determined by the force applied, so it is also possible to bend thick sheets.

- For materials that require, however, a high tonnage load and a more precise angle, we recommend the hollow bottom fold or coining, which is obtained by pressing the part inside the matrix.

- Finally, flattening (or bottom bending) is a type of fold that is mostly used to avoid free edges and obtain more rigidity.

Start now with the best bending for your sheet metal projects

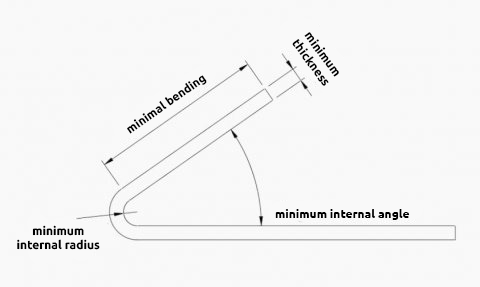

The K Factor

A designer in the industrial sector knows well that in sheet metal bending it is necessary to pay close attention to the K factor, that is what is generally called “springback“. Each material has, in fact, different mechanical properties that come into play when it is deformed. The K factor is the ratio between the thickness of the sheet and the axis of the neutral fiber, or between the distance between the inside of the bend and the neutral plane and its workpiece thickness. While the neutral plane is the area that does not vary during bending, and neither shortens nor lengthens. We can say that the K factor can be summarized as: r / T> 1.

Guide to sheet metal design on the Niuo price estimator

- You can choose 7 different types of steel and 5 different sheet thicknesses.

- Each single piece can be produced if contained within a sheet development with a maximum surface area of 1000 x 1000 mm.

Respect of times

Once the order is confirmed, Niuo ensures delivery on time and is committed to ensuring that the deadlines are met.

Repeatability

Thanks to the precision and accuracy of the processing, it will be possible to produce repeatable pieces based on the required quantities.

Ready to get started?

Upload the file of your project to know the costs and time required for implementation.

Everything can be different. The impossible becomes possible.

The possible becomes simpler.

Everything can be different. The impossible becomes possible.

The possible becomes simpler.

Follow us on our social

Contact Niuo Customer Care experts to find different solutions together and receive support.