3D printing technology for designers

Prototyping becomes smart and agile.

- Print your prototype online

- Check the mechanical characteristics

- Repeat, and let the mass production begin!

Multi Jet Fusion 5210 technology

Plastic materials

Turn your projects into solutions

With Niuo you can test your ideas instantly and improve your know-how, online. The quote estimator is the tool that allows you to know exactly the price of 3D printing and sheet metal bending services.

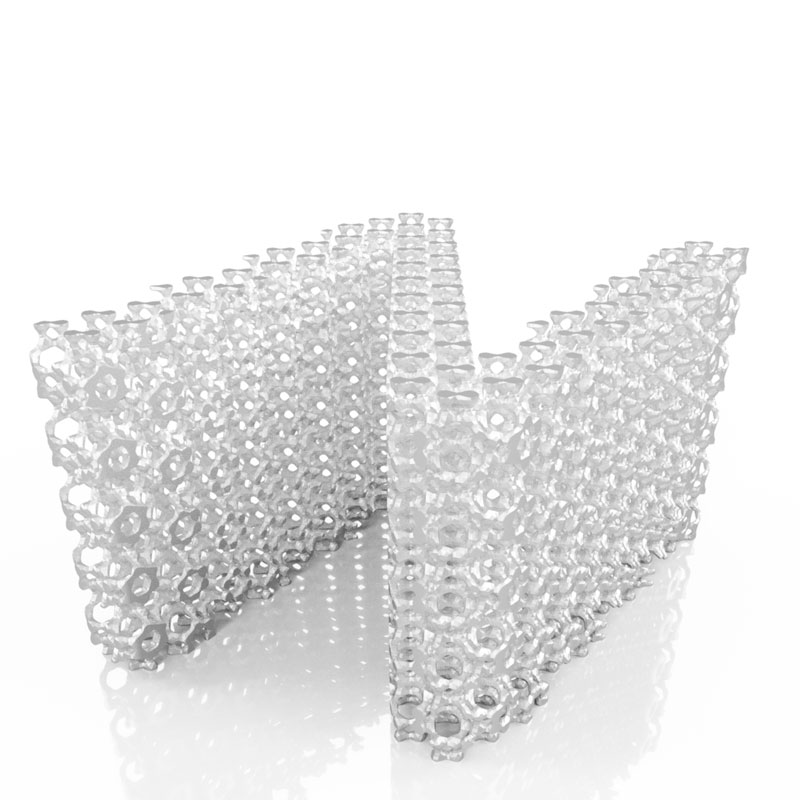

HP MultiJet Fusion

Powder bed fusion 3D printing technology.

Girbau DY 130

Excellent Touch and Feel effect to parts produced with HP MJF technology.

Made in Italy 3D prints

Guaranteed high standards and 100% “Made in Italy” process.

Made in Italy 3D printing

Discover a new way of designing online: agile and intuitive, and above all “Made in Italy”

A world of designers, filled with formulas and equations, where every detail is perfectly calculated through elaborated softwares and great experience in the field. Niuo opens the way to rapid and intuitive prototyping, to make the complex work behind 3D printing smart.

Find out the online price now and test your ideas

Before starting the mass production, you can quote your prototype via the online estimator. You have the possibility to change the variables, to see in real time the price changes of the 3D printing service.

Before starting, remember that you can upload your projects in two types of formats: STL and STP / STEP.

New trends in printable materials

The advantages of PA12

Although currently in the 3D printing market there are large companies operating in the automotive or aeronautics sectors, which challenge production with a wide range of materials for 3D printing, to date PA 12 is the lightest thermoplastic technopolymer. It is highly widespread and used thanks to its organoleptic properties and its fields of application, PA 12 has the lowest water absorption and high resistance to impact and chemical agents.

The characteristics of PA12

Naylon PA 12 - The data reported come from tests carried out within the HP.

| HP 3D HR PA 12 | Axis (XY) | Axis Z | Test method |

| Tensile strength (Mpa) ⁱᵛ | 50 | 50 | ASTM D638 |

| Tensile strength (Mpa) ⁱᵛ | 1900 | 1900 | ASTM D638 |

| Elongation at yield (%) | 10 | 8 | ASTM D638 |

| Elongation at break (%) | 17 | 9 | ASTM D638 |

| Impact resistance (kJ/m) | 4.2 | 3.8 | ASTM D256 |

| Density (g/cm³) | 1.01 | 1.01 | ASTM D792 |

ⁱⁱ. Using HP3D HR PA12 material, 20% update ratio, balanced print profile, natural cooling, and measured aer bead-blasting with glass beads at 5-6 bar;

ⁱⁱⁱ. Following all HP recommended printer setup and adjustment processes and printheads aligned using a semi-automatic procedure;

ⁱᵛ. The typical variation in tensile strength (95% of parts) falls within the 45-55Mpa range, while the tensile modulus values remain in the 1650-2200Mpa range;

ᵛ. Using the Izod A test method with notched specimen @ 3.2 mm according to the ASTM D256 standard;

ⁱ. The strength and elongation criteria are reported by the ASTM (American society for testing and materials)

Finishes of the PA 12

Nesting: the printing method that optimizes time and costs

A technology able to reduce costs drastically.

3D printing can involve the use of large resources in terms of time and costs. However, the latest printing technologies, thanks to the “Nesting” mode, use print builders capable of matching the area available to the builder and the overall area of the pieces to be finalized. For this reason, the more pieces you can “organize” inside the build itself, the less the cost of the outputs.

Respect of times

Repeatability

Ready to get started?

Everything can be different. The impossible becomes possible.

The possible becomes simpler.