High-performance thermoforming

We support professionals and companies with reliable, accurate and highly customizable models.

Our expertise in 3D printing allows us to offer state-of-the-art thermoforming models designed to meet the needs of the most technical and specialized industries. Thanks to Multi Jet Fusion (MJF) technology and the use of PA12 material, we combine precision, reliability and a high degree of customization, guaranteeing excellent results and consistent performance.

Our thermoforming models are not classifiable as medical or orthodontic devices. We offer advanced 3D printing services, providing high-quality technical solutions to support companies and professionals in their projects.

Unmatched accuracy and definition

MJF technology allows you to create models with extremely fine details, faithfully reproducing complex geometries for flawless results.

Consistent quality

Each model is made with strict quality control, ensuring consistent results and reliability that exceeds expectations.

Innovation and versatility

Our technology offers unique possibilities to face production challenges in an innovative way, responding to the demands of an ever-changing market.

Performance material

PA12 guarantees mechanical strength, lightness and an excellent surface finish, fundamental characteristics for technical and precise use.

Dedicated price

Only for this type of product, thanks to the performance and reliability offered by MJF technology, we can guarantee a fixed price of € 3.89 for the production of each individual model.

Speed and reliability

We understand how crucial production time is. We guarantee shipments within 5 working days, but in most cases we can complete production and shipping in just 3 working days.

Custom-designed to support professionals

Our thermoforming models integrate into your production processes, offering tailor-made solutions for every technical need.

Choose a reliable partner for precision, speed and quality without compromise.

Online quotation

Place an order for thermoforming models in a few simple steps

Access our dedicated quote, choose how you want to share your models and place an order. The cost of each model is € 3.89 andour quotation system is designed to simplify and speed up the request process with shipping in 3 days.

If you are not yet registered, create an account to access our dedicated estimater. Once logged in, You can choose between two ways to share your templates to us, depending on your needs.

You will be assigned a Family Technical from our team of experts who will take care of verifying the material uploaded or sent and who, in the event of possible anomalies or price changes, will promptly report the deviations when accepting the order.

Mode 1 - .zip Archive

If you choose this mode, you will be able to upload a .zip archive containing your models. Our system will automatically analyze the files, identifying the amount of models in it. This option is ideal for files that are less than 500 MB in size.

Mode 2 - External File Transfer Service

With this mode, upload your models using an external file transfer service. You will need to generate a sharing link that allows our technicians to access the files and enter it in the appropriate field. We’ll also ask you to manually specify the number of templates in the link.

How to properly prepare a model for 3D thermoforming

Technical guidelines to obtain optimized .stl files, avoiding common errors and ensuring maximum efficiency in the production process.

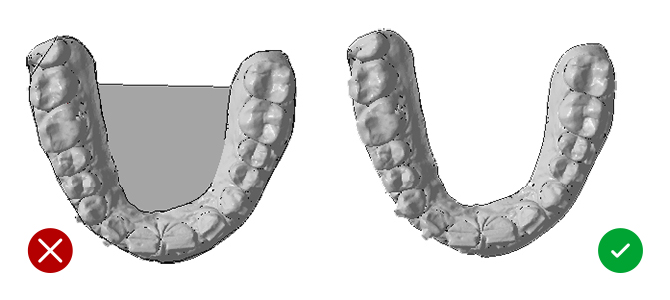

GEOMETRY

The model must have a U-shape with a flat bottom base, with no closing surfaces.

This configuration is essential to ensure an optimal result

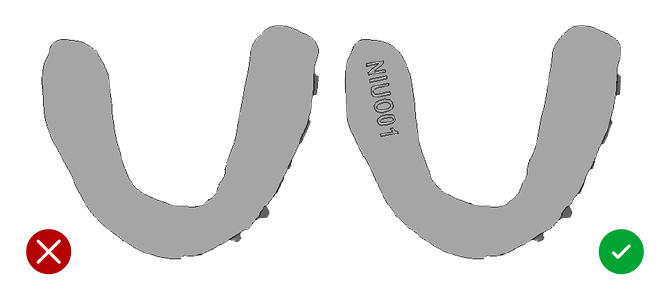

REFERENCES

Each model must have a clear and well-defined reference, positioned laterally or in the lower base.

This is crucial to facilitate identification and simplify management during all phases of the production workflow

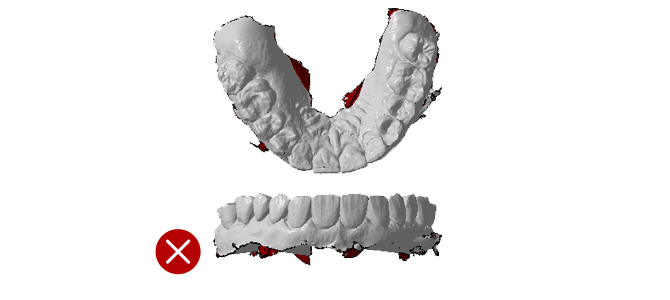

SCAN ERRORS

The CAD files used are generally derived from reverse engineering processes by scanning.

It is essentialto verify that the resulting file is free of errors or jagged surfaces that could compromise its quality

Number of meshes

The qualityof the CAD file is determined by the number of triangular meshes that define its geometry. However, too many meshes can increase the file size (.stl) to levels that negatively impact production efficiency. Based on our experience, we recommend that the optimal size of a standard CAD file is between 1O MB and 20 MB.

Geometry

The model must have a U-shape with a flat bottom base, with no closing surfaces.

This configuration is essential to ensure an optimal result

References

Each model must have a clear and well-defined reference, positioned laterally or in the lower base.

This is crucial to facilitate identification and simplify management during all phases of the production workflow

Scan errors

The CAD files used are generally derived from reverse engineering processes by scanning.

It is essentialto verify that the resulting file is free of errors or jagged surfaces that could compromise its quality

Number of meshes

The qualityof the CAD file is determined by the number of triangular meshes that define its geometry. However, too many meshes can increase the file size (.stl) to levels that negatively impact production efficiency. Based on our experience, we recommend that the optimal size of a standard CAD file is between 1O MB and 20 MB.

Highest quality, starting from the production process

From density management to pattern orientation, every step of MJF printing is optimized for accuracy, durability, and flawless surfaces.

Precision, accuracy and quality are essential requirements to ensure thermoforming models that live up to expectations. For this reason, production using MJF technology follows specific protocols: density optimization and strategic orientation.

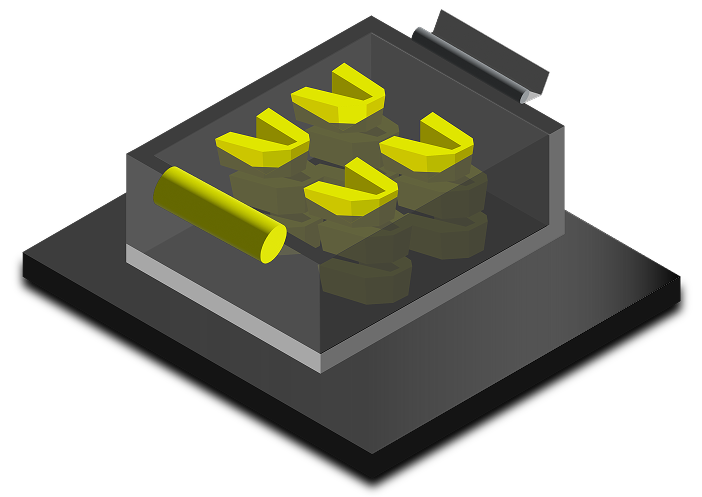

Density optimization

Each model is hollowed out, leaving a wall with a minimum thickness of 1.45 mm. This minimizes heat development during the process, preventing unwanted surface defects.

Strategic orientation

The models are oriented with the planar base facing upwards. This configuration reduces the risk of localized collapse due to the weight of the PA12 powder used in the process. In addition, it promotes an upward heat flow that helps to smooth the surface, ensuring a final result of the highest quality.

Find out how we can help you

Rely on our expertise to produce superior thermoforming models. Contact us today and find out how our services can help you complete your projects with precision, speed and innovation

Frequently asked questions

RFQ Quote: Get a detailed quote for machining, services, and finishes.

Does Niuo produce medical and/or orthodontic devices?

No. For this specific type of product, the Niuo team carries out the production of items through additive manufacturing processes (3D printing with MJF technology) ensuring the highest quality and accuracy, which are in no way classifiable as medical devices.

Our product, in fact, represents the model that will be used by professionals in the sector to create the product they need.

Was this helpful? Make a quote now

Does Niuo make dental alignment aligners?

Was this helpful? Make a quote now

Does the file I share for production already need to be emptied?

No, our production technicians will take care of the file emptying operations. Make sure that your file does not have any type of error that compromises its feasibility, reflects the required specifications and that it has the appropriate size (in MB), we will take care of the rest!

Was this helpful? Make a quote now

How can I order?

For thermoforming models , our website has a special dedicated section.

If you are not already a user for the service dedicated to the production of thermoforming models, you will first need to register an account. If you are already a registered user for this type of service, you will only need to log in.

Once logged in, you can visit the dedicated estimator and choose which way to share the models is best suited to your needs. There are two available.

- Mode 1 – .zip archive

By choosing mode 1 you will be able to share your template files using a .zip archive. Once you have created the archive with your models, simply upload them. The system will analyze it and automatically identify the amount of models within it. This mode is suitable for archives smaller than 500 MB - Mode 2 – external service for file transfer. By choosing mode 2, you will have to use an external file transfer service. You will then have to create a special link for sharing, making sure that our technicians can actually access it, and paste it in the appropriate field. You will then have to manually indicate the number of models it contains.

Whether you choose mode 1 or mode 2, simply press the button at the bottom of the page and complete the process to send us your request and share your models.

Our experts will evaluate your request and your models within 24 hours. If no critical issues are found and the feasibility analysis is passed, you will be sent a link through which you can confirm your order by making the advance payment with one of the available methods.

Was this helpful? Make a quote now

If my models do not meet the required specifications, will they still be produced?

Unfortunately not. The offer reserved for thermoforming models is closely linked to their specific production method. Therefore, if your models do not meet the required specifications they will unfortunately not exceed feasibility and your pre-order will be cancelled.

Was this helpful? Make a quote now

When will my thermoforming model order be shipped?

In the case of thermoforming models, the fulfillment (i.e. shipment) of an order is guaranteed within 5 working days from the confirmation of the order, which coincides with the receipt of payment (N.B. in the case of bank transfer from the date of crediting of the amount).

In almost all cases, however, an order for thermoforming models is processed in 3 working days.

Was this helpful?

Make a quote now