Post-processing and Finishes

The post-processing of the parts printed with HP MJF 5210 technology takes place in various steps:

- Shot peening (carried out on all parts produced with MJF);

- Chemical Smoothing (Optional);

- Pigmentation (Optional).

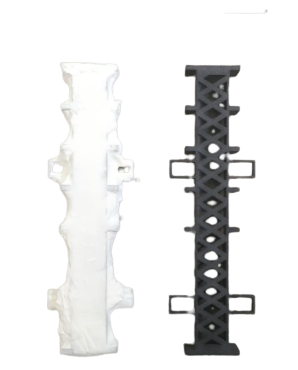

Shot peening

Shot peening is a process performed on all parts, whether they are then subjected to coloring or not, following the printing phase with HP Multi Jet Fusion 5210 technology. The purpose of shot peening is to remove excess powder resulting from the printing process and to achieve an excellent Touch and Feel effect.

Parts produced with HP Multi Jet Fusion 5210 technology have an inherent level of surface roughness and porosity that is not changed with standard shot peening.

To reduce these aspects, Niuo offers different shot peening post-processing options with different mediums:

- Niuo Micro Glass, finishing post-processing that uses glass microspheres to impart a better level of roughness than standard shot peening.

- Niuo Shot Surfacing, in which shot peening is done using plastic microspheres, giving parts an intermediate level of surface roughness;

- Niuo Ceramics micro, finishing post-processing that gives the lowest level of surface roughness among the available post-processings, in which shot peening is done using ceramic microspheres.

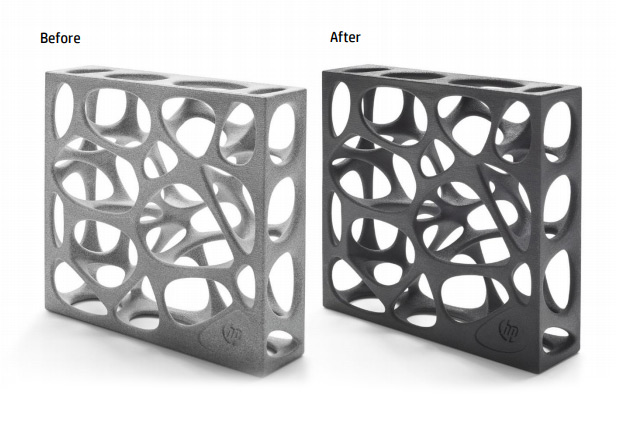

Vapour smoothing

Vapor smoothing is a surface finishing process for parts produced through 3D printing techniques.

In this process a solvent is first vaporized and then allowed to settle on the part’s surface. Upon contact, the solvent acts as a “smoother,” effectively dissolving the surface layer without material removal, sealing surface porosities and any present micro-cavities. The parts are then left to dry, allowing the solvent to fully dissipate. This process covers all part surfaces, whether visible or not.

Chemical smoothing results in a glossy surface with enhanced color depth, characterized by minimal surface porosity and drastically reduced roughness. Additionally, it reduces or even eliminates minor natural imperfections and printing layer lines.

In terms of mechanical properties, the process improves part strength and wear resistance, increases elongation at break, and provides a degree of impermeability.

Chemically smoothed parts can subsequently undergo additional treatments, such as pigmentation.

This finishing process, suitable for a wide range of materials, is particularly effective for parts produced with MJF technology, enhancing their aesthetic and surface quality to levels comparable with parts made through other production methods, such as injection molding.

Pigmentation

The coloring of parts produced with HP Multi Jet Fusion 5210 technology is an optional post-processing. This can be accomplished by pigmentation or painting.

PIGMENTATION

This is a process for obtaining black-colored parts by immersing them in a high-tech bath of a specific pigment solution, imparting color uniformity and improving aesthetics, but keeping mechanical and dimensional properties unchanged. It is achieved through the best technology on the market, specially designed and manufactured by GIRBAU.

Different options are available on our platform.

Top Black One

Economic Black finishing can be performed on 3d parts made with HP MJF5210 technology. It involves a bath on coloring equipment loaded with specific pigments.

Top Black Two

Performed on 3d parts made with HP MJF5210pro technology.

The excellence of this finish involves a very high-tech bath on GIRBAU dyeing equipment specially designed for the treatment of 3D printed parts with HP systems. The dye bath is loaded with specific, highly selected pigments.

Following the pigmentation stage, the part treated with Top Black (The Best Black), receives further treatment, in this case of specific painting, with high-tech systems that bring out the depth and integrity of the coloration.

All parts executed with this finish turn out to be of the highest aesthetic grade with extraordinary results for excellent durability with an intense black.

The indicative thickness of the treatment is an average of 77 microns.

PAINTING

Process to make matte black, semi-gloss black or other color parts using water-based spry paints.

Different options are available on our platform.

RAL 9005 MATT (Spry Paint)

Finishing with RAL 9005 MATT is done on 3d printed parts with HP technology using professional in Spry Paint system. The treated part results intense and homogeneous. Indicative thickness of the treatment 100 microns.

RAL 9005 SEMI SHINY (Spry Paint)

Finishing with RAL 9005 SEMI GLOSS, is done on 3d printed parts with HP technology using professional spry paint system. The treated part results intense and homogeneous, slightly glossy. Indicative thickness of the treatment 100 microns.

RAL BY CHOICE (Spry Paint)

Finishing with RAL BY CHOICE is done on parts printed in 3d with HP technology with professional system in Spry Paint using a color of your choice identified by a specific RAL (to be indicated during quotation). The treated part results intense and homogeneous. Indicative thickness of the treatment 100 microns. The feasibility of this solution may depend on availability of the indicated RAL and the run to be made.

Start with your model.

Turn your projects into solutions to grow evolve and innovate yourself.

With Niuo you quickly test your ideas and improve your know-how, online. The estimator is the tool that allows you to know the exact price of 3D printing and sheet metal bending services.

Plastic materials

In Niuo you will find a selection of materialsfor both processes: materials for 3D printing and for sheet metal bending. Niuo is constantly looking for thermoplastics, specialty filaments and other 3D printer solutions.

CONSULT THE ARCHIVE

Guidelines

A short guide with simple rules to get the result you want. If you have doubts consult it, to set up your project to perfection with STL, OBJ and others format.

READ THE GUIDELINES

Confirm on file?

You can ask the Niuo experts to check this out for you.

READ MORE

Contact the Niuo Customer Care experts to find different solutions together and receive support.

Follow us on our social networks

Respect of the times

Once the order is confirmed, Niuo ensures delivery on time and undertakes to ensure that the deadlines are respected.

Repeatability

Thanks to the precision and accuracy of the machining it will be possible to produce repeatable pieces based on the required quantities.

Ready to get started?

Upload the file of your project to know the costs and time required for implementation.

Everything can be different. The impossible becomes possible.

The possible becomes simpler.