3D printing, CNC, and industrial machining for your digital supply chain

A complete ecosystem of advanced technologies to optimize production

SCALABLE PRODUCTION

From high-precision CNC machining to 3D printing to complete packaging and printing solutions, we offer a flexible production model that is suitable for every step: from prototype to series production. An integrated approach designed to optimize development times and adapt quickly to market needs.

MATERIALS AND TECHNOLOGIES

We adopt the latest generation technologies to optimize every phase of the production process, ensuring precision, efficiency and control. We work with certified high-performance materials, including engineering polymers and stainless steels, to offer components that are durable, reliable and industrial-grade finishes.

INDUSTRIAL PRECISION

Each phase of the production process is managed within a supervised industrial system, which ensures dimensional consistency, constant quality and reliability. Precision comes not only from the use of advanced technologies, but also from optimized procedures for the control and finishing of parts, in line with the most demanding industry standards.

SINGLE POINT

OF CONTACT

We act as a centralized hub in an integrated manufacturing ecosystem, collaborating exclusively with specialized partners. The strategic presence in the area guarantees continuous direct supervision and traceability. This model simplifies operations, optimizes the supply chain and ensures a single technical reference up to the finished product.

Manufacturing innovation for strategic industries

How to Get an Instant Quote

Get an estimate for work and services in seconds thanks to our instant quote.

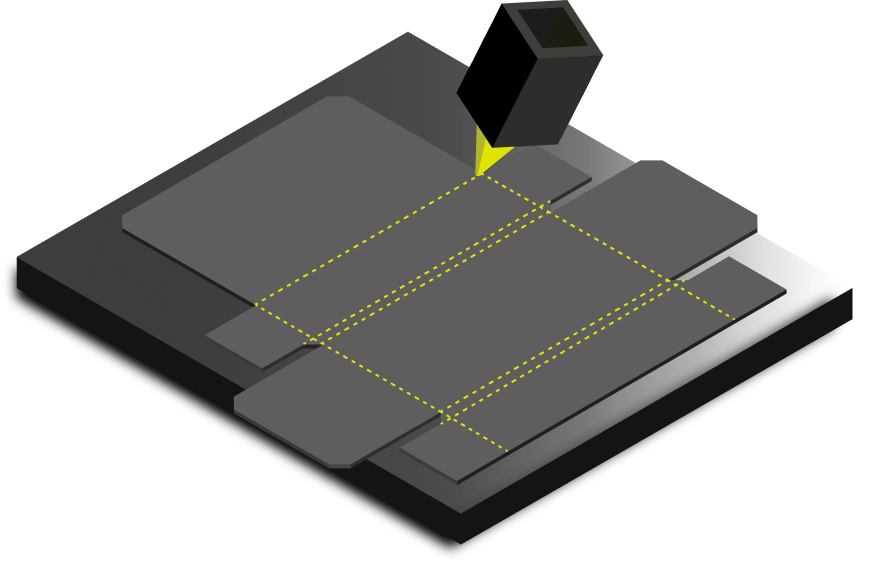

1- INSTANT QUOTE

Log in with your credentials or register in seconds. Upload your files to the platform and start the 3D printing quoting process.

2- SELECT THE PROCESS

Choose from CNC machining, 3D printing, sheet metal fabrication, injection molding, and welded assemblies. Set technical parameters, select materials, and define machining, finishing, and delivery time specifications.

3- ORDER ONLINE

Immediately receive a detailed quote for your project with HP MJF technology and confirm the order with online payment in total safety.

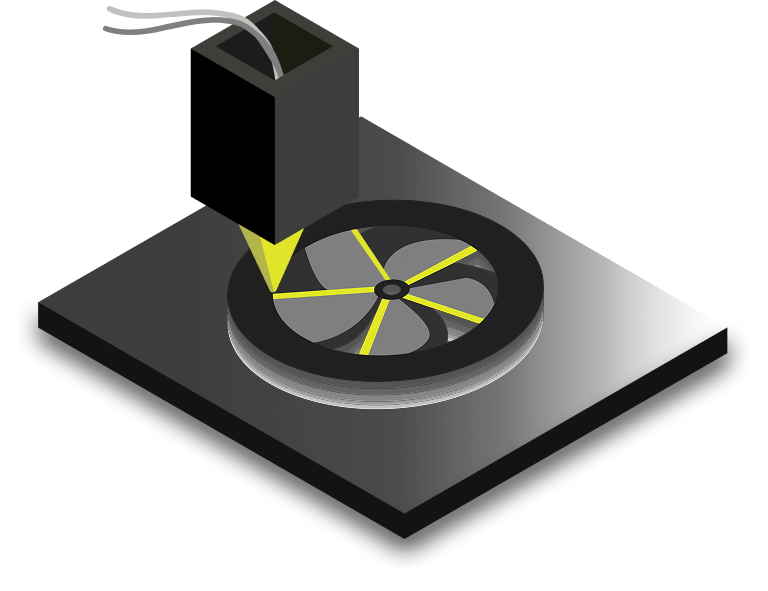

4- TRACK YOUR ORDER

Follow the progress of production from your personal area and receive your printed parts on schedule.

Quotation via RFQ

For complex requests and prints with FDM technology, we offer a dedicated quoting system

The parts submitted for RFQ are analyzed by our team of professionals and partner companies, ensuring optimal solutions in terms of feasibility, materials and production processes. Upload your files and select technical and material specifications. Once the analysis is complete, you will receive your personalized quote and can proceed to confirm the order with online payment.

Upload your files, select the specifications and receive the quotation

Concrete results and satisfied customers

Read verified reviews and be inspired by the quality of our services.

From quotation to delivery

Efficiency, safety and simplicity for your production. Every step of the process is designed to ensure transparency and reliability.

TRANSPARENT and tailor-made QUOTES

For HP MJF 3D printing, we offer automatic quoting with instant pricing. If the file has complex geometries, the system will notify you of the transition to the RFQ process. For all other services and any finishes, the RFQ is always necessary and allows a detailed technical analysis and a personalized quotation.

EASY

REGISTRATION

Log in in just a few steps. Creating an account is quick and intuitive: register and access the platform now to upload your files and get instant quotes.

SECURE

PAYMENT

Finalize your orders in total security with certified payment methods. Our system ensures secure transactions for risk-free purchase management.

TRACKABLE

DELIVERIES

Track the status of your order at every stage and receive the parts made on time. We work with reliable logistics partners to ensure safe and timely shipments.

Frequently asked questions

Everything you need to know about orders and shipping

What is the procedure for placing an order on Niuo?

Ordering on Niuo is simple, fast and designed to adapt to every production need. You have two operating modes available:

- Automatic quoting (available for 3D printing with HP technology): Upload your 3D file, select material, finish, and quantity. The system generates an instant quote and allows you to complete the order in a few clicks, with active tracking from your reserved area. In the case of particularly complex geometries or large quantities, the system will automatically notify you of the need to switch to RFQ mode for a thorough technical evaluation.

- Request for Quotation (RFQ): For all other services — CNC machining, FDM 3D printing, sheet metal processing, injection molding, welded assemblies, packaging, typography and thermoformed products — a dedicated RFQ system is active. Simply upload the files and specify the project requirements: you will receive a detailed and tailor-made quote from our technical team quickly.

In both cases, the process is completely digital, with dedicated assistance, full traceability and real-time updates on the status of the order.

How do I request a quote on the platform?

- Upload your project file (preferably in . STEP. STP or . STL) directly in the dedicated area.

- Select the desired manufacturing process : CNC, 3D printing, sheet metal processing, injection molding, welded assemblies, packaging, typography, or thermoforming.

- Set the technical parameters: material, finish, quantity, any specific notes , and required delivery time.

What types of files do you accept and in what format?

- tag. STEP/. STP – Preferred format for CNC, sheet metal, stamping, and assembly machining: Allows for detailed technical analysis of the 3D model.

- tag. STL – Ideal for 3D printing, it is used for automatic quoting and direct production.

- tag. IGES/. IGS, . DXF, . DWG – Compatible to attach specifications of on-demand machining, such as sheet metal cutting.

- .PDF – Useful for attaching technical drawings, dimensional indications or additional notes.